Bending

capabilities

BENDING

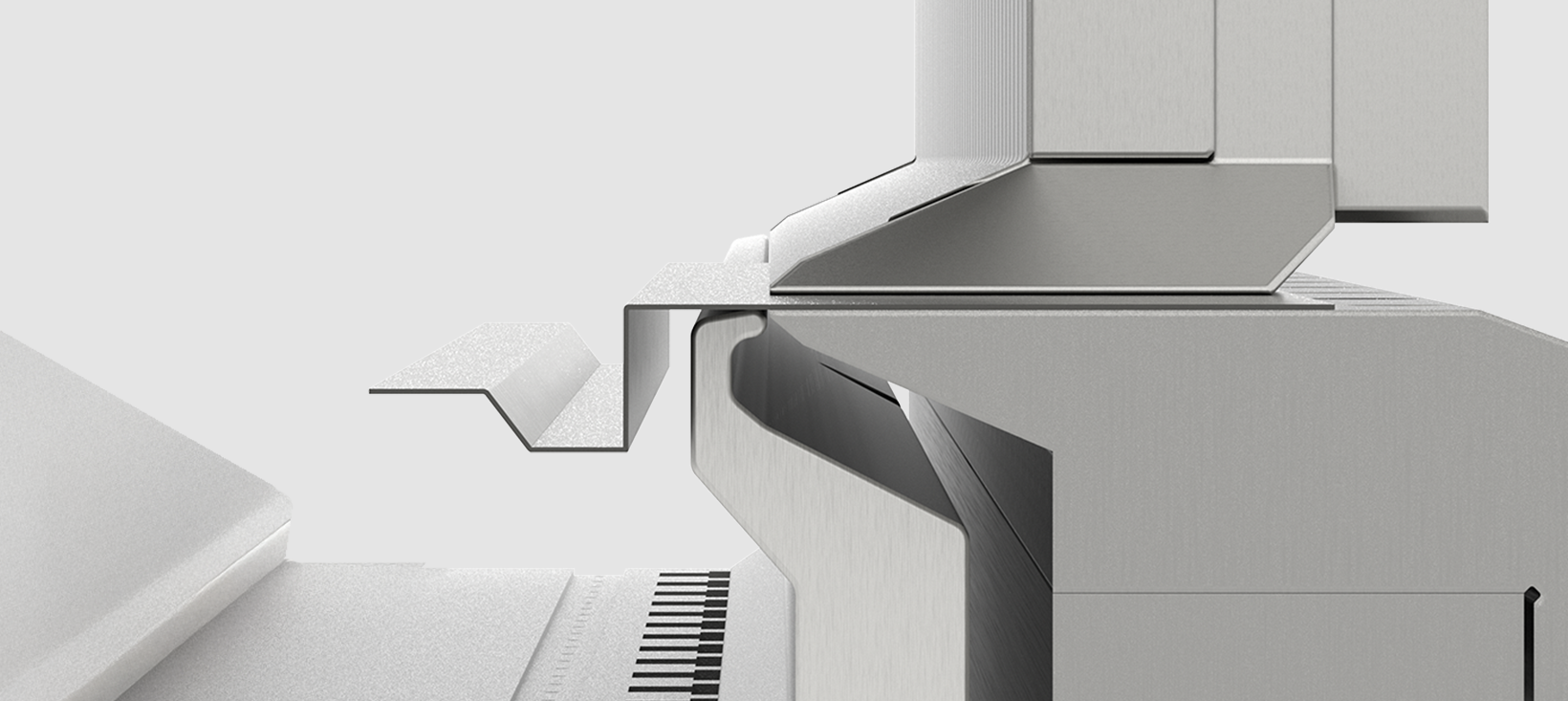

The blades and the blankholder perform both upward (positive) and downward (negative) bends

Clamping and handling

The manipulator clamps the sheet and automatically moves and rotates it during bending

LOADING AND UNLOADING

Manual loading, automatic positioning. At the end of the cycle, the panel moves backward for easy pickup

4 standard multi-purpose bending tools to process the entire range of thickness and materials.

MX uses upper and lower bending blades that make upward and downward bends on each side of the sheet.

The role of the blankholder is to hold the sheet during bending.

Each MX is equipped with a manually adjustable blankholder, which can be set according to the size of the panel to be bent.

It features two symmetrical side segments that allow contraction of up to 30 mm. The blankholder is modular and can be adjusted in 10 mm steps.

Responsible for handling the sheet during bending, it is composed of a manipulator, a clamp, and a rotator. The sheet is centered then automatically manipulated, clamped, and rotated.

The sheet is centered only once using mechanical stops at the beginning of the cycle.

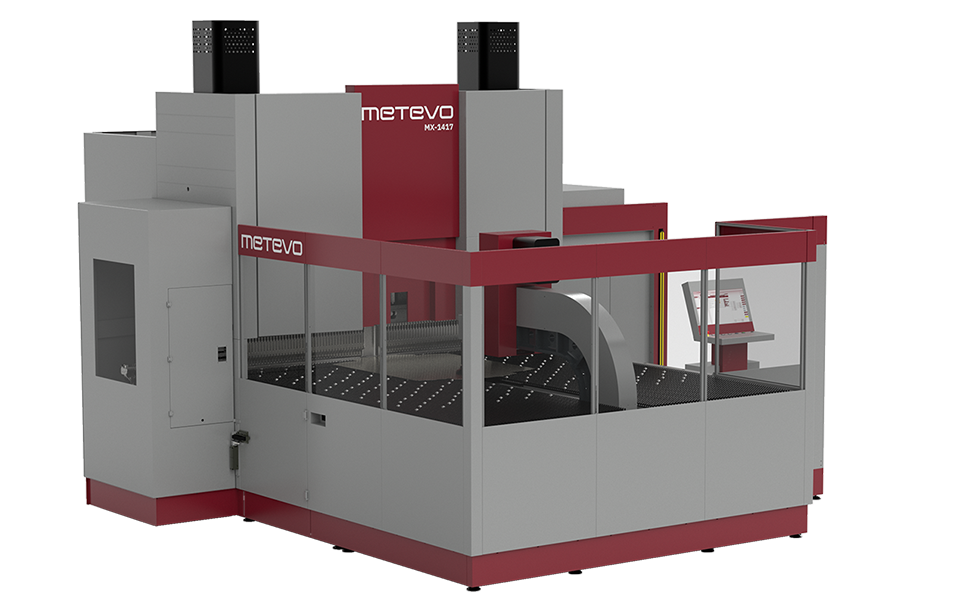

MX Series

MX-1417

| Bending length | 1400 mm |

| Bending height | 170 mm |

MX-2017

| Bending length | 2000 mm |

| Bending height | 170 mm |

MX-2517

| Bending length | 2500 mm |

| Bending height | 170 mm |

MX panel bender it is the right choice for companies seeking efficiency, simplicity, and competitive costs, while taking their first step toward bending automation

The perfect solution for:

| More productive than a traditional press brake | |

| More affordable than a high-end panel bender | |

| Repetitive production and medium-to-high volumes |